Are you in the middle of a pivot?

Pivot is the word on everyone’s lips right now, and there have been some incredible examples of innovation in recent weeks; LEGO making face masks, gin companies making hand sanitiser, to name just two. It’s all about making the most of your core competency, a regular topic I discuss with my coaching clients.

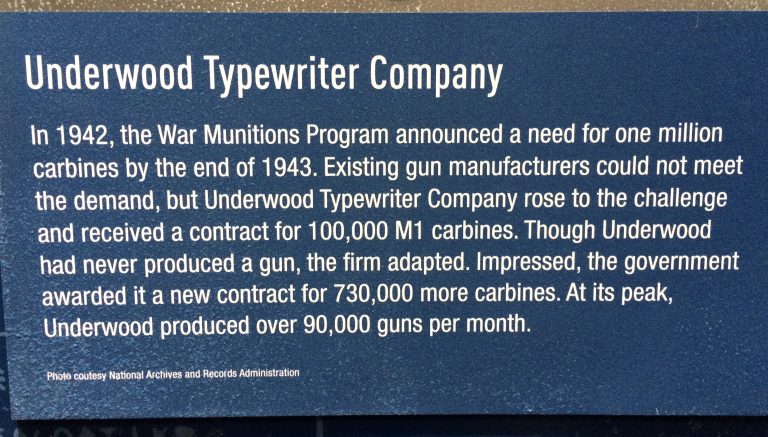

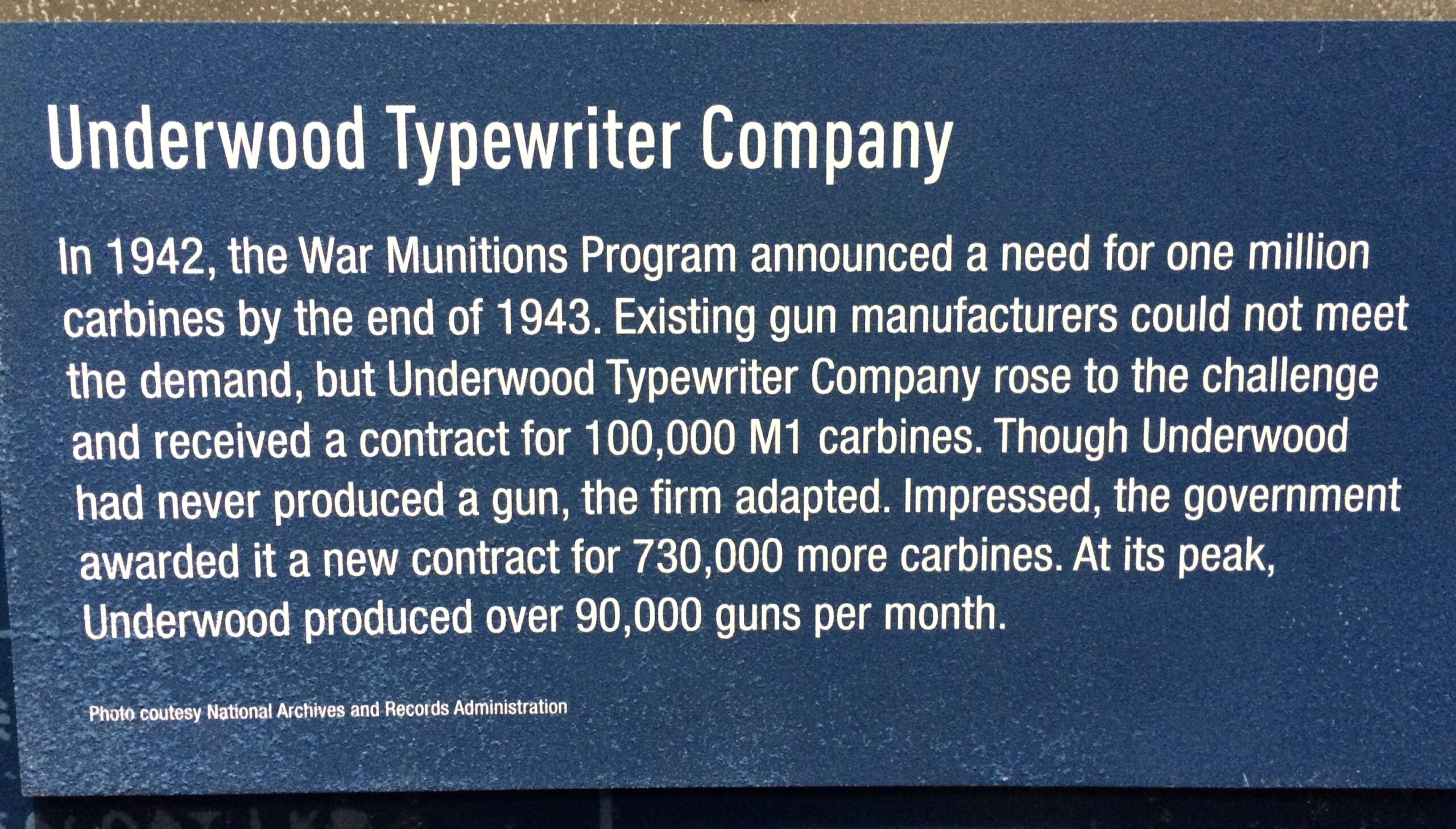

This type of ‘pivot’ often happens in times of crisis. One little-known success story is the Underwood Typewriter Company, which played a key role in boosting the arsenal of the US Army during World War II, manufacturing the M1 Carbine, a lightweight, semi-automatic firearm.

In 1942, the War Munitions Program announced a need for one million carbines by the end of 1943. Existing gun manufacturers could not meet the demand, but Underwood rose to the challenge and received a contract for 100,000 M1 Carbines.

Though Underwood had never produced a gun, the firm adapted.

They were the first to deliver test samples to the proving grounds. In fact, of all the manufacturers of the M1 Carbine, Underwood produced the highest number of parts in their own facilities.

Impressed, by mid 1943, the US Government awarded Underwood additional contracts for almost 730,000 carbines.

The company quickly found innovative ways to make sure that the carbines fixed sights were on target, and speeded up inspection and delivery substantially. As a result, Underwood, built ranges in the factory and developed a quick method using targeted telescopic sight.

Underwood was also first to produce stamped and brazed parts by producing trigger housings and front sights reducing time and machines for complex work during milling operations.

At its peak, Underwood was test firing and targeting 3,000 guns a day. They grew more and more efficient and eventually achieved production of carbines as high as 90,510 per month.

It is thought that they made about a million carbines from late 1942 to late 1944 and during the post-war period, were one of two civilian companies awarded a contract to refurbish M1 carbines.

Underwood is a great example of using your core competency to pivot and serve a new market need.

How are you serving your customers right now? Are you in the middle of a pivot? What else would your underlying competencies enable you to do?